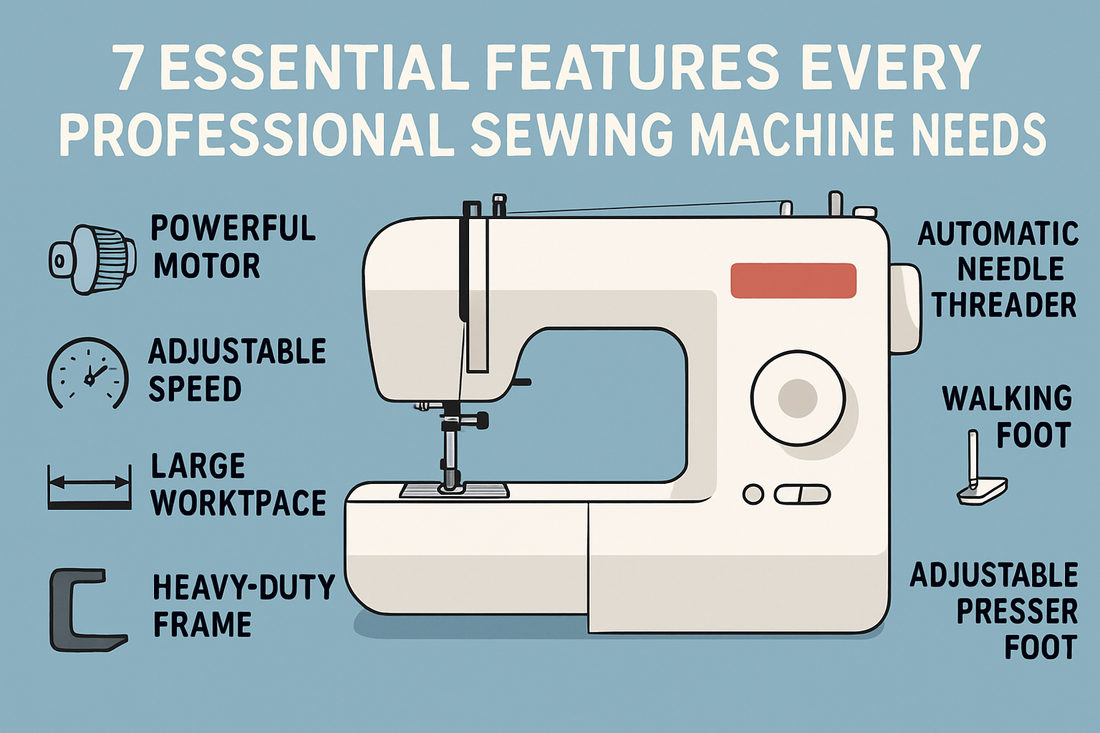

7 Essential Features Every Professional Sewing Machine Needs

Share

Understanding the Professional Sewing Machine Landscape

The realm of professional sewing encompasses a sophisticated ecosystem where precision engineering meets creative artistry. Professional-grade sewing apparatus transcends the boundaries of casual crafting, demanding robust construction and specialized capabilities that can withstand intensive production schedules while maintaining exemplary stitch quality. Whether you're establishing a boutique atelier, expanding your quilting enterprise, or transitioning from hobbyist to professional seamster, understanding the fundamental attributes that distinguish professional machinery becomes paramount.

Modern professional sewing machines represent decades of technological advancement, incorporating computerized systems, precision mechanics, and ergonomic design principles. These machines serve as the cornerstone of successful sewing operations, where reliability directly correlates with productivity and profitability.

Advanced Motor Systems and Power Distribution

The heart of any professional sewing machine lies within its motor assembly and power distribution network. Industrial-grade servo motors provide consistent torque delivery across variable speed ranges, ensuring uniform stitch formation regardless of fabric density or operational tempo. Unlike standard domestic machines that utilize universal motors, professional units employ sophisticated brushless DC motors or AC servo systems that generate substantially higher needle penetration force.

This enhanced power translates to effortless navigation through multiple fabric layers, heavyweight materials, and challenging textile combinations. Professional motors typically deliver between 1,000 to 1,800 stitches per minute while maintaining consistent thread tension and stitch formation. The superior power-to-noise ratio ensures comfortable working environments during extended operational periods.

Variable Speed Control Technology

Professional-grade speed regulation systems incorporate electronic feedback mechanisms that provide precise control across the entire operational spectrum. Microprocessor-controlled speed modulation allows practitioners to adjust machine velocity incrementally, facilitating delicate detail work at reduced speeds while maintaining full power availability for production runs.

Precision Stitch Formation and Timing Mechanisms

The hallmark of professional sewing machinery lies in its ability to produce consistent, precise stitches under diverse operational conditions. Advanced timing mechanisms coordinate the intricate dance between needle, hook assembly, and feed system with microsecond precision. This synchronization ensures optimal loop formation, thread capture, and lockstitch completion across varying fabric weights and thicknesses.

Professional machines incorporate hardened steel components within their timing assemblies, reducing wear and maintaining accuracy throughout extended service intervals. The hook and needle timing relationship remains stable, preventing skipped stitches, thread breaks, and tension irregularities that can compromise professional results.

"The difference between amateur and professional results often lies not in the operator's skill alone, but in the machine's ability to consistently execute precise stitch formation under challenging conditions."

Advanced Hook Systems

Professional sewing machines utilize sophisticated hook mechanisms, including rotary hooks, oscillating hooks, or specialized hook configurations designed for specific applications. These systems feature enlarged bobbin capacities, smooth thread paths, and precision-machined surfaces that minimize friction and thread stress during high-speed operation.

Comprehensive Feed System Integration

Professional sewing operations demand versatile feed mechanisms capable of handling diverse fabric characteristics and sewing techniques. Multi-directional feed systems incorporate differential feed capabilities, allowing precise control over fabric movement during seam construction. This technology proves essential when working with stretch fabrics, preventing puckering and distortion while maintaining seam integrity.

The feed dog configuration in professional machines typically features increased height and specialized tooth patterns designed to engage various fabric textures effectively. Adjustable presser foot pressure systems complement the feed mechanism, providing optimal fabric control without compression damage to delicate materials.

Differential Feed Capabilities

Advanced differential feed systems enable independent control of front and rear feed mechanisms, accommodating fabric pairs with dissimilar stretch characteristics. This functionality proves invaluable for professional garment construction, quilting applications, and specialty textile processing.

Pfaff Professional Sewing Solutions

When evaluating professional sewing machine options, the Pfaff collection stands as a testament to German engineering excellence and innovative design philosophy. These machines incorporate many of the essential professional features discussed, including robust motor systems, precision stitch formation, and advanced feed mechanisms that professional sewists rely upon for consistent results.

Pfaff's professional lineup addresses the diverse needs of serious sewists, from precision quilting systems to heavy-duty construction machines capable of handling industrial applications. Their integrated sensor technology, automatic threading systems, and computerized stitch regulation represent the pinnacle of professional sewing machine evolution.

Automated Threading and Cutting Systems

Professional productivity demands efficient workflow optimization, where automated threading and cutting systems eliminate time-consuming manual operations. Advanced automatic threading mechanisms guide thread through the entire needle path, from spool to needle eye, reducing setup time and minimizing threading errors that can interrupt production flow.

Integrated cutting systems provide clean, precise thread trimming at the completion of each seam or upon command activation. These systems typically include both needle thread and bobbin thread cutting capabilities, leaving appropriate thread tails for subsequent operations while maintaining workspace organization.

Needle Threading Precision

Professional automatic needle threaders accommodate various needle sizes and thread weights, utilizing mechanical or pneumatic systems to ensure reliable thread insertion. This functionality proves particularly valuable during extended sewing sessions where eye strain and fatigue can impact threading accuracy.

Thread Trimming Integration

Programmable thread trimming systems allow customization of cutting timing and thread tail length according to specific application requirements. Professional machines often include both automatic and manual cutting modes, providing operational flexibility across diverse sewing scenarios.

Enhanced Workspace and Ergonomic Design

Professional sewing operations require expansive workspace areas to accommodate large projects, intricate quilting assemblies, and commercial production requirements. Extended free-arm configurations provide increased clearance for bulky items, while enlarged throat spaces facilitate maneuvering of substantial fabric assemblies.

Ergonomic considerations become paramount during extended operational periods, where machine positioning, control accessibility, and workspace illumination directly impact operator comfort and productivity. Professional machines incorporate adjustable components, intuitive control layouts, and superior lighting systems designed to reduce operator fatigue.

| Workspace Feature | Professional Specification | Benefits |

|---|---|---|

| Throat Space | 10+ inches | Accommodates large quilts and garments |

| Free Arm Length | Extended configuration | Improves accessibility for circular seams |

| Work Surface | Smooth, enlarged platform | Supports fabric movement and reduces drag |

| Lighting System | LED array with brightness control | Reduces eye strain and improves precision |

Illumination Systems

Professional-grade LED lighting arrays provide shadow-free illumination across the entire work surface, with adjustable brightness levels and color temperature options. This advanced lighting technology reduces eye strain while enhancing stitch visibility and precision during detailed operations.

Digital Control Interface and Programming

Contemporary professional sewing machines integrate sophisticated digital control systems that provide comprehensive operational management through intuitive touchscreen interfaces. These systems enable precise parameter adjustment, stitch pattern selection, and operational monitoring that enhances both productivity and creative capabilities.

Advanced programming functionality allows storage of custom stitch combinations, tension settings, and operational parameters for specific projects or fabric types. This digital memory capability ensures consistent results across production runs while reducing setup time for recurring operations.

Touchscreen Integration

High-resolution touchscreen displays provide immediate access to machine functions, stitch libraries, and operational status information. Professional interfaces incorporate logical menu structures and customizable display options that accommodate individual operator preferences and workflow requirements.

Memory and Storage Capabilities

Professional machines typically include substantial internal memory for storing custom patterns, embroidery designs, and operational settings. External connectivity options enable pattern importation, firmware updates, and data backup capabilities essential for commercial operations.

Durability and Service Accessibility

Professional sewing machine construction emphasizes longevity and serviceability, incorporating robust materials and accessible component layouts that facilitate maintenance and repair operations. Cast metal frames provide stability and vibration resistance, while precision bearings and bushings ensure smooth operation throughout extended service intervals.

Service accessibility becomes crucial for professional operations where downtime directly impacts productivity and profitability. Professional machines feature modular component designs, accessible adjustment points, and comprehensive diagnostic systems that simplify troubleshooting and maintenance procedures.

- Cast metal construction for enhanced stability and longevity

- Precision-machined components with extended wear characteristics

- Accessible lubrication points for routine maintenance

- Modular design facilitating component replacement

- Comprehensive diagnostic systems for troubleshooting

- Professional service network availability

The investment in professional sewing machinery represents a commitment to quality, productivity, and creative excellence. These seven essential features form the foundation upon which successful professional sewing operations are built, providing the reliability, precision, and capabilities necessary to transform creative visions into tangible results. Whether pursuing artistic quilting endeavors, establishing garment production capabilities, or expanding existing sewing operations, understanding these fundamental characteristics ensures informed decision-making in professional equipment selection.